Oil filter

Remove the filter on the suction pipe in the tank of the tunnel mucking loader, and remove the filter core to clean it. And check the mesh for damage and openings that are too large. For the filter with the tunnel mucking loader shell, remove the tunnel mucking loader shell and drain the hydraulic oil inside, and clean the inside, and check for rust and damage at the same time. Check whether the action of the monostable valve is normal. Pay attention not to hurt the mesh of the filter core when installing, and pay attention to the pressing method of pressing.

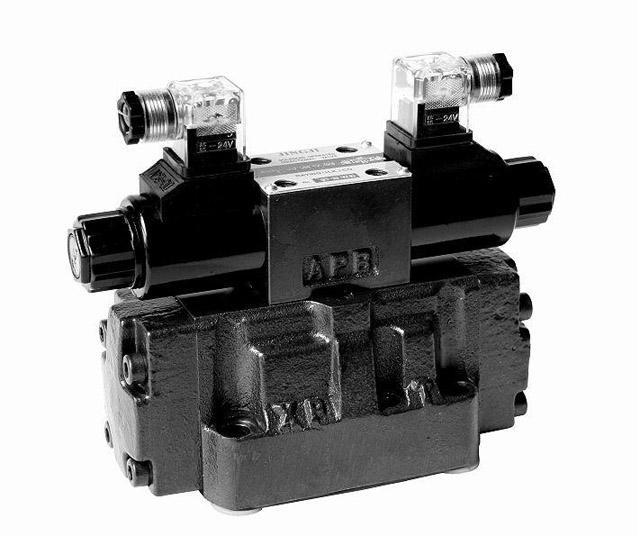

Pressure regulator

The inspection procedures for pressure-controlling valves, pressure-reducing valves, sequence valves, counterbalance valves, etc. are as follows: Disassemble and inspect the contact surfaces of the pilot valve and the valve seat. . In addition, check whether the spring is deformed, damaged, whether the O-ring is loose and deformed, etc., and manually determine that the main shaft is sliding smoothly. tunnel mucking loader

When inspecting the tunnel mucking loader, the pointer of the pressure gauge is vibrating, the movement is slow and the phenomenon of instability, etc., you should take this opportunity to carefully check the operating status of the internal components of the tunnel mucking loader. The pressure reducing valve, safety valve, sequence valve, etc. are operated less frequently, so it is enough to check it in 3 months. The direct-acting pressure control valve is also the same. However, it still depends on the actual situation, which is not the case. It should be judged with the hearing of the human ear. If it is abnormal, it should be decomposed for detailed inspection. In addition, if there is an odor, the material of the coil edge may be bad. Pay attention to check to prevent the coil from burning out. During the daily inspection, it is found that the magnetic noise and temperature rise after power-on. You should take this opportunity to break down the tunnel mucking loader for inspection.